Metallurgy is one of the oldest industries in the world. It has always played a critical role in economies, as the production of iron and steel is essential for tools, machinery, and technical equipment. This sector focuses on the production of ferrous and non-ferrous materials.

Metal production is a highly complex process that requires expertise and creativity. Furthermore, high-quality metal casting demands pure metals that meet the highest standards. Companies and factories operating in this field use state-of-the-art equipment and innovative technologies. In Alberta, the oldest foundry is Norwood. The story of its establishment and the unique features of its work are detailed further on edmonton.name.

The History of Norwood Company

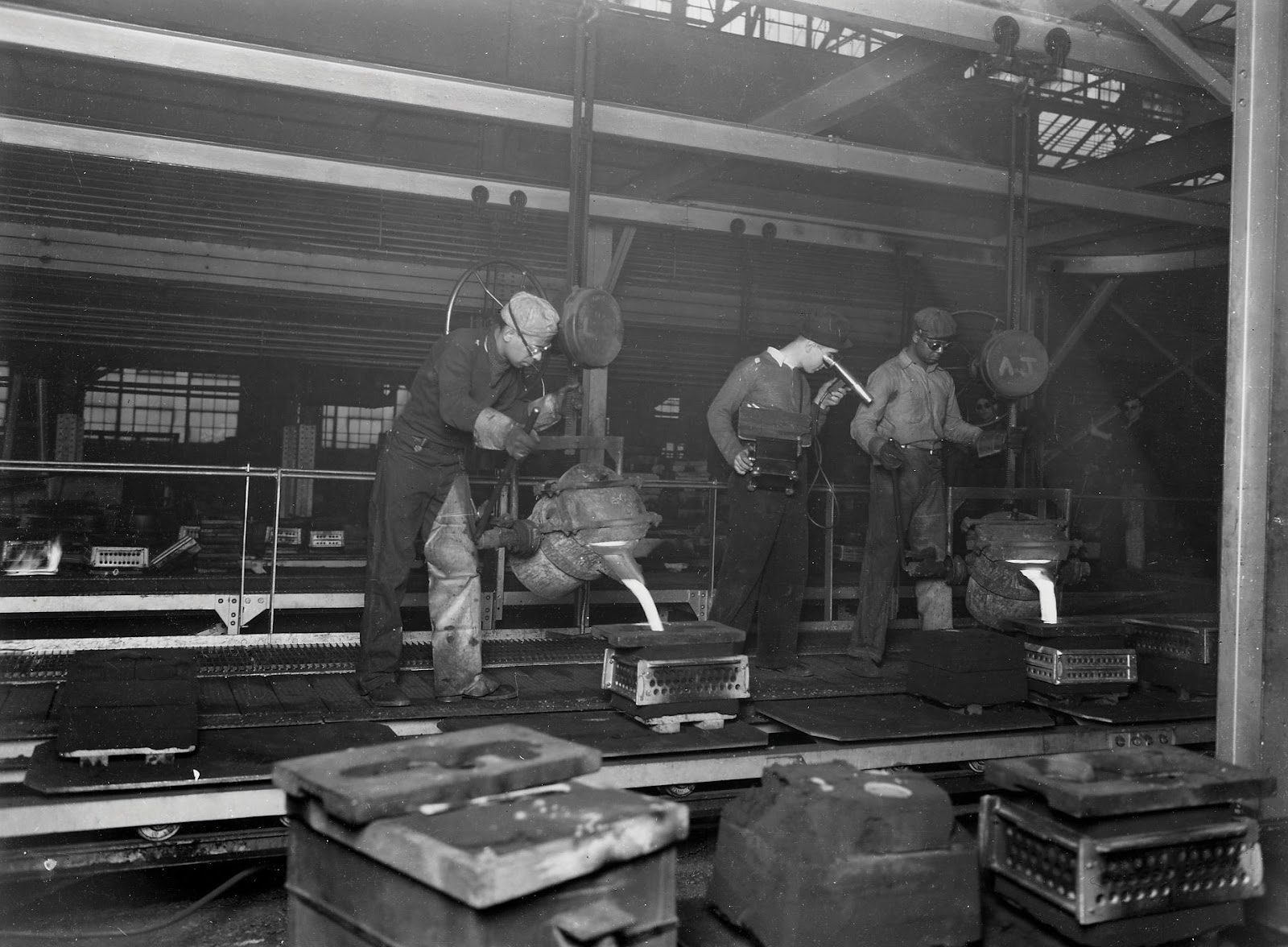

The Norwood Foundry was established in 1922 by Hearn and his colleagues. Five years after its inception, Hearn sold the enterprise to Ernest Booker, who managed Norwood for 50 years. Throughout its history, Norwood acquired foundries in various Canadian cities and successfully expanded its metallurgical production.

In its early years, most of the factory’s products were focused on agricultural equipment, such as cast-iron plates for preparing livestock feed.

During World War I and World War II, the company’s main products included stove parts and agricultural components. By the Second World War, the business began to thrive, and the company expanded. In 1946, Norwood acquired the Garvie Bolton Foundry and soon after, purchased the Coutts Machinery Company Ltd.

The Growth of Norwood

In the 1950s, Edmonton experienced urban growth, development of the automotive industry, and expansion of energy infrastructure. During this period, the demand for steel surged, leading Norwood to acquire a new foundry in Edmonton. This became the third plant under its management.

In 1952, to improve production efficiency, the factory in Garvie Bolton was closed and consolidated with operations at 10054-79 Avenue. Both the Norwood and Edmonton plants produced cast iron, brass, and aluminum. By 1956, the Edmonton plant specialized in non-ferrous metals and cast iron, employing around 300 workers at the time.

In 1978, Norwood built a new foundry in Nisku. The modern facility produced high-alloy iron castings melted in electric induction furnaces. Alberta’s oil industry became the primary market for Norwood’s products. At the same time, the company manufactured and supplied essential components for the waterworks sector, including hydrants, valves, pipes, and sewer elements.

One of the largest castings was a 4,500-pound iron sphere, produced for the Syncrude oil sands processing plant.

In 1992, the company built an extension to the Nisku plant, which was integrated with the existing workshop. This optimization led to the closure of the original production site at 111 Avenue and 91 Street. That same year, the Norwood Foundry shut down its 70-year-old plant at the intersection of 91 Street and 111 Avenue in Edmonton. According to a historian, while the plant was not an architectural marvel, its closure marked the end of an entire era.

Norwood’s Modern Operations

The remaining factories were equipped with new, advanced machinery. Old furnaces were replaced with modern, computerized equipment. The Norwood foundry in Nisku has been operating for many years, continuing to produce castings for the construction and oil and gas industries. Thanks to specialized equipment, the plant’s operations have minimal impact on the environment, ensuring that it does not pollute the city’s ecosystem.

Norwood remains a significant player in Alberta’s metallurgical sector, combining its rich history with modern innovation.